Electrification of Process Heaters

Author - Sidharth Garg, Process Engineer, FIS

December 2025

1. Industrial pilots are currently underway to "de-risk" the technology, paving the way for wider adoption as equipment matures.

2. Radiant technology wins because it handles the difficult services (high temp, dirty feedstocks) that other electric methods (immersion/indirect) cannot.

3. The Bottom Line: High efficiency (98%) helps close the cost gap, but carbon pricing (>$30/ton) is usually required to make the OPEX favorable.

Key Takeaways

Recently at FIS, we’ve noticed an increase in inquiries from clients exploring electric process heater projects. This signal encouraged us to share our perspective on the current state of this technology—and the key technical and economic trade-offs that define any successful electrification project today.

This growing interest in electrification is not happening in a vacuum. It is a direct response to the global energy transition and the critical role industrial facilities play in managing emissions. Within a refinery or petrochemical plant, no single category of equipment is a larger focal point than the fired heater fleet. In a typical plant, approximately 75% of all energy consumed is burned in fired heaters and steam boilers, making them the primary target for any meaningful emissions reduction strategy.

This theoretical potential is now being tested at an industrial scale, with several major chemical companies launching ambitious pilot programs to prove the viability of electric heating for their most demanding services. The most prominent examples are found in steam cracking, one of the most energy-intensive processes in the industry. Collaborations such as Shell and Dow in the Netherlands, and a separate joint effort by BASF, SABIC, and Linde in Germany, are developing and constructing multi-megawatt electric cracking furnaces intended to eventually replace traditional fossil fuel-fired units. It is important to note that these pioneering efforts are significantly supported by government incentives, receiving funding from bodies like the Dutch Government and Germany's Federal Ministry for Economic Affairs and Climate Action to help de-risk the technology. These programs are creating a viable pathway for electrifying core industrial processes, paving the way for wider adoption as the technology matures.

With that context, the purpose of this article is to move beyond the headlines and provide a practical engineering framework for these projects. We will break down the available technologies, analyze the critical economic trade-offs, and outline a clear path to assessing feasibility for your specific application.

Background

Refresher on process requirements

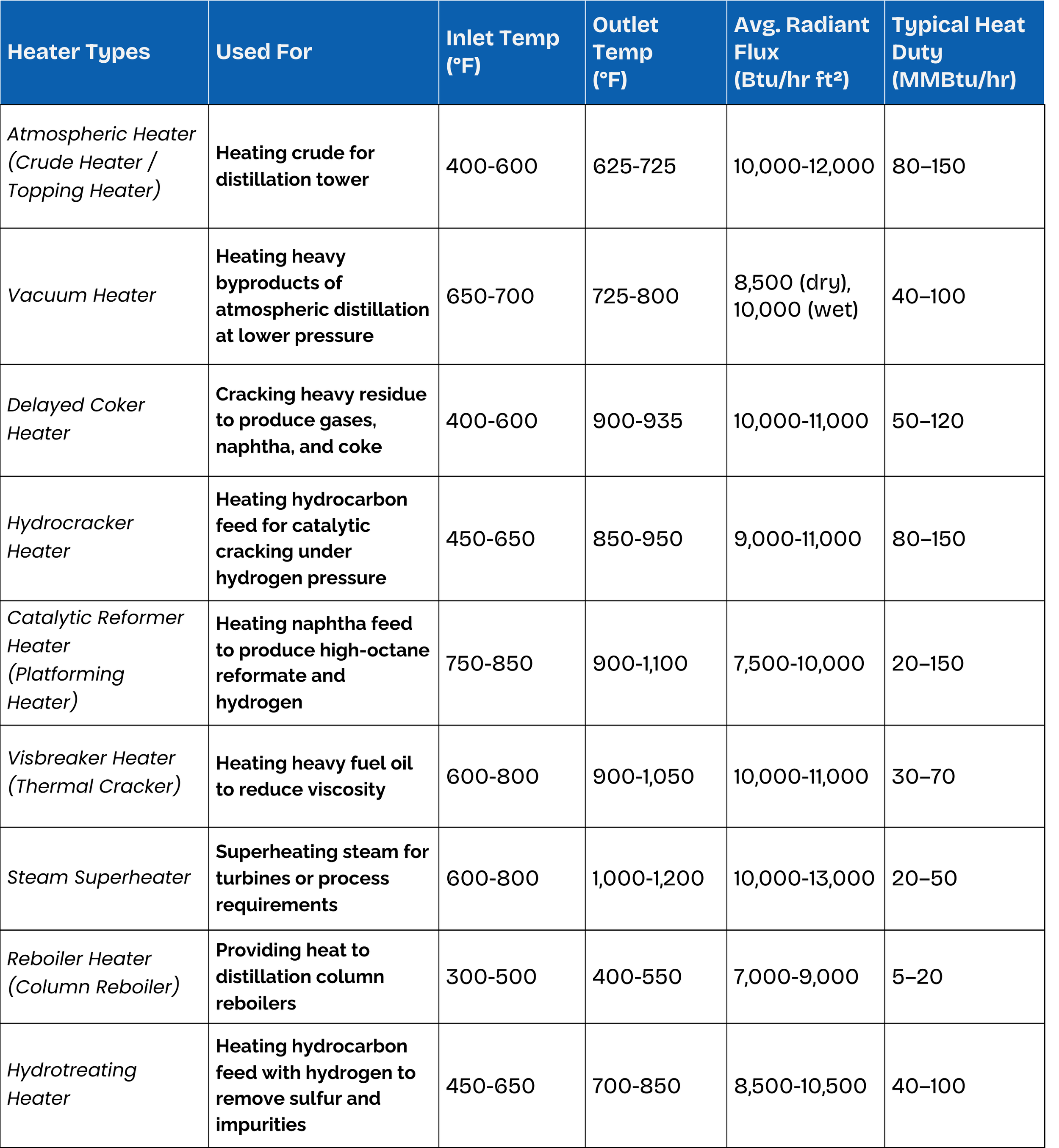

Before exploring the specifics of electrification, it's helpful to establish a baseline for the equipment it aims to replace. The following table provides a brief refresher on common fired heater applications in a refinery, along with their typical operating temperatures, heat flux requirements, and a sense of their heat duty scale.

This data provides the critical benchmark for any potential replacement. The fundamental question, which we will explore next, is how the various electric heating technologies measure up against these demanding, long-established process requirements.

Table 1: Typical Operating Conditions for Common Refinery Heaters.

Note: Specific operating conditions and duties are highly dependent on the unit's capacity, feedstock, and specific process design.

An Overview of Electric Heating Technologies

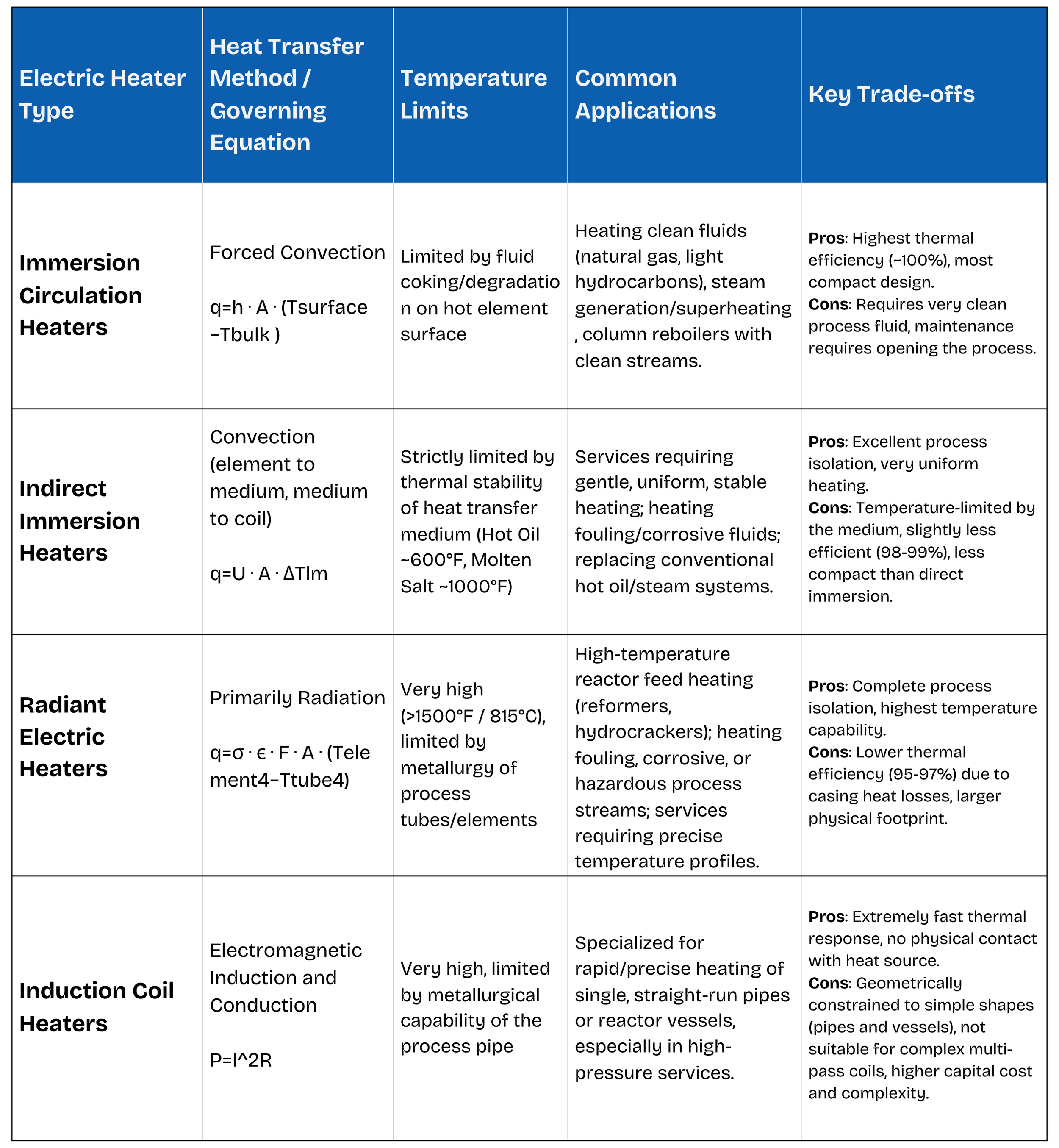

We will review four technologies, each with unique principles of operation, applications, and limitations

Immersion Circulation Heaters - An immersion circulation heater is an electric heating system in which flanged or screw-plug heating elements are installed inside a pressure-rated vessel or chamber through which the process fluid is pumped (circulated). As the fluid flows across the heated elements, it quickly absorbs heat and exits the heater at the required temperature

Indirect Immersion Heaters - This design provides process isolation by using an intermediate heat transfer medium. An immersion heater bundle is placed inside a larger vessel filled with a medium like hot oil or molten salt. A separate process coil is also submerged in this medium, which absorbs the heat.

Radiant Electric Heaters - This technology is the direct electrical analogue to a conventional fired heater. The process coil is housed inside a refractory-lined chamber. High-temperature electric elements are mounted on the walls or a central bridgewall and transfer energy through radiation to the process coil without direct contact.

Induction Coil Heaters - An external coil powered by a high-frequency alternating current is wrapped around a conductive process pipe. This creates a magnetic field that induces powerful electrical currents directly within the pipe wall, causing the pipe itself to become the heat source.

The radiant electric heater emerges as the most versatile and strategically sound solution for the broadest range of refinery applications. It is the only design that combines the complete process isolation required for challenging feedstocks like crude oil with the extremely high-temperature capabilities needed for reactor services. Given this versatility, we will use the radiant electric design as the reference point for assessing the feasibility of replacing fired heaters.

Table 2: Comparison of Electric Heating Technologies

Technical Comparison: Fired & Electric Heaters

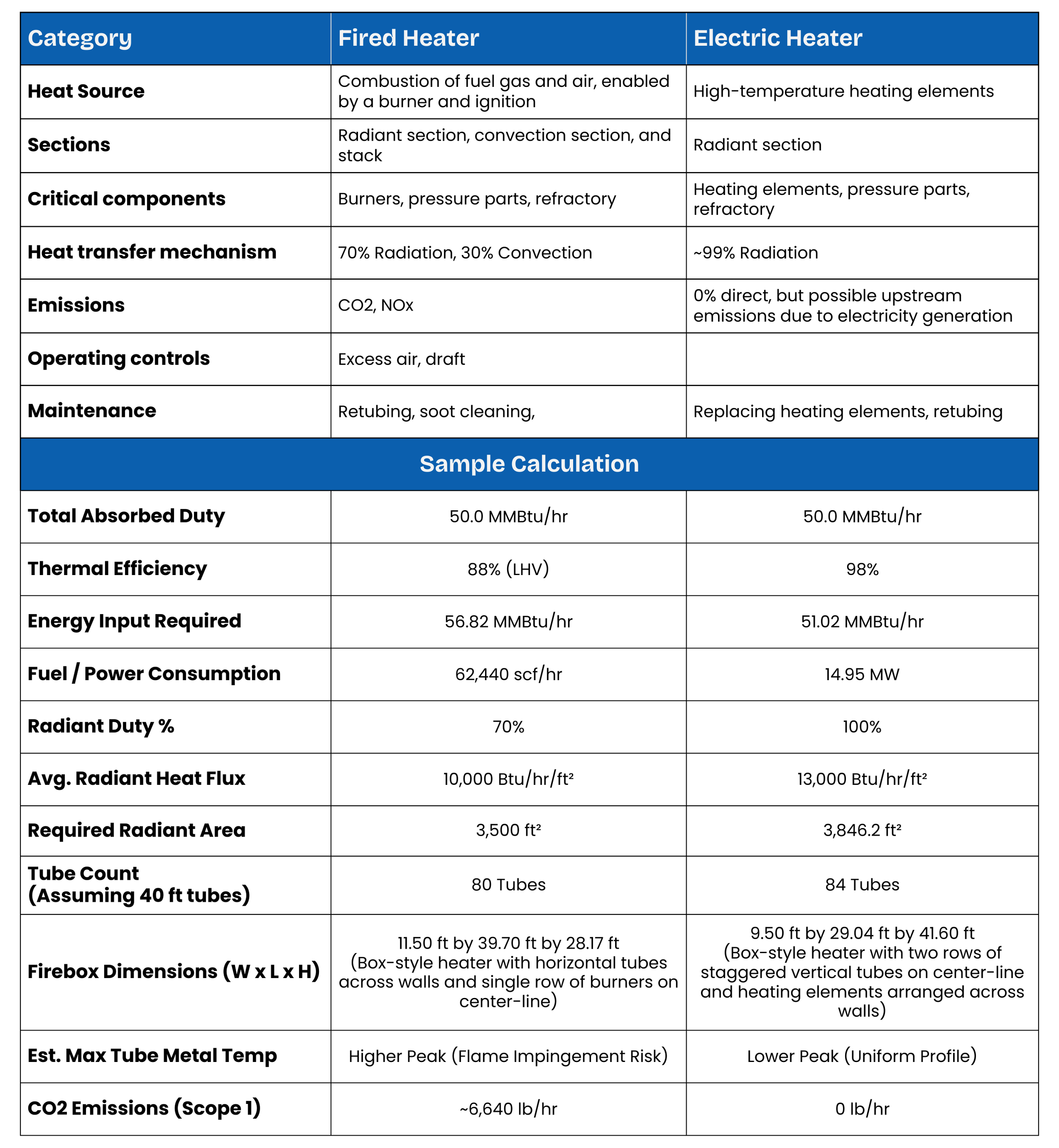

To visualize the fundamental shift in heater design, the table below contrasts the key mechanical components and operating parameters of a traditional fired unit against a radiant electric alternative.

We have also included a sample calculation for a 50 MMBtu/hr service to illustrate the efficiency gains and resulting energy load requirements.

Table 3: Technical Comparison Between Electric and Fired Heater

Balancing the Costs: A Framework for Economic Analysis

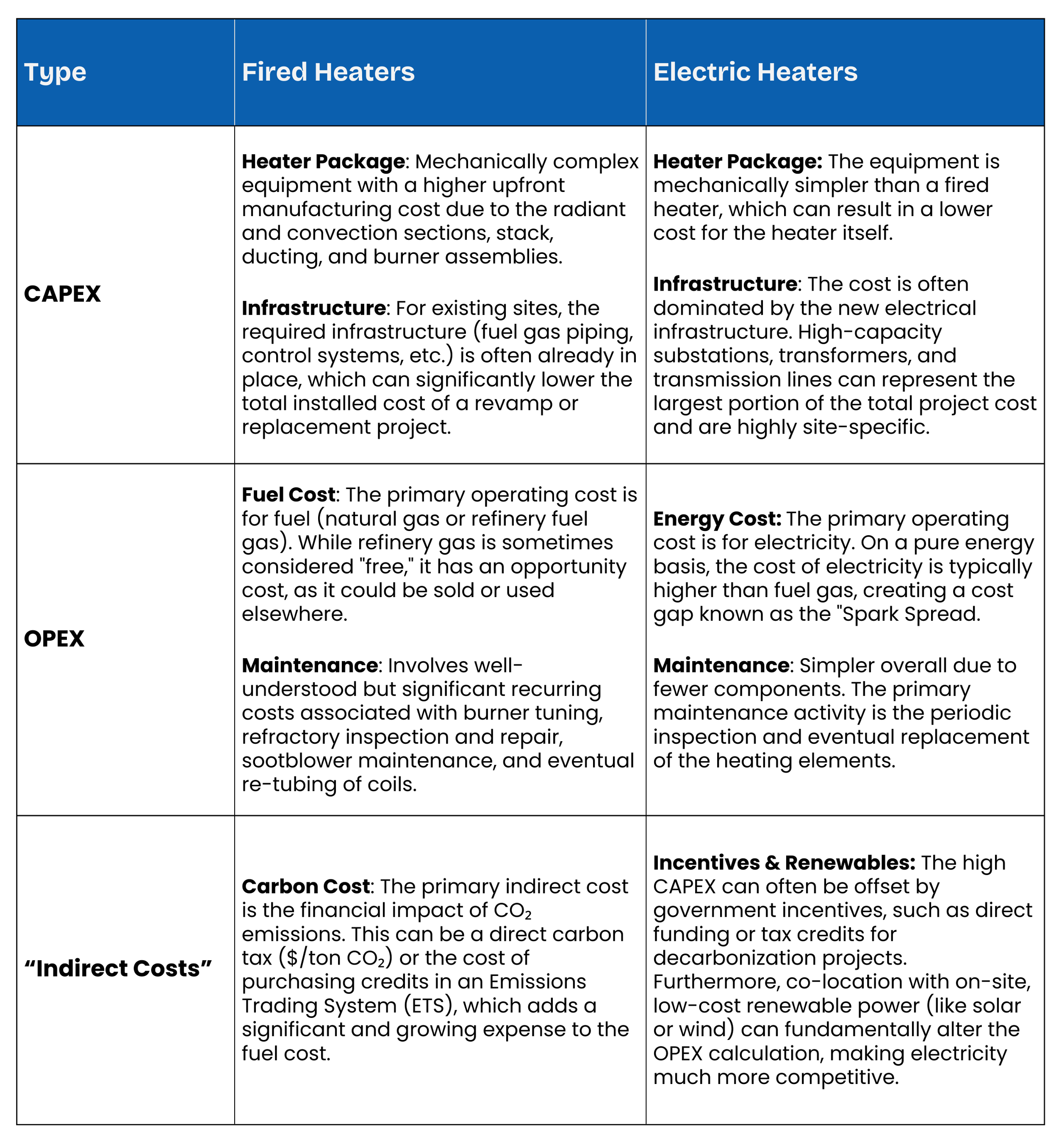

While the technical options for electrification are well-defined, the decision to proceed with a project ultimately hinges on a thorough and realistic economic analysis. This is more than a simple comparison of equipment prices; it involves a holistic assessment of upfront capital investment (CAPEX), long-term operating expenses (OPEX), and the growing financial impact of carbon policy. The following table provides a framework for this evaluation, breaking down the key economic drivers for both conventional-fired heaters and their electric alternatives.

Table 4: Economic Analysis Between Fired and Electric Heaters

Feasibility Analysis: Is Electrification Right for Your Application?

With a clear understanding of the technology, the decision to electrify a process heater comes down to a site-specific feasibility study. This analysis moves beyond generalities and focuses on three core components: the initial capital investment, the operating cost spread, and the strategic impact of carbon pricing.

The Capital Hurdle: It's More Than Just the Heater Cost

Before any operating costs are considered, the primary hurdle is the capital expense (CAPEX). As discussed, the cost is often dominated not by the heater package itself, but by the required electrical infrastructure. A true feasibility study must begin with a budgetary analysis of any required substations, transformers, and high-voltage cabling needed to support a multi-megawatt continuous load.

The Operating Cost: Calculating Your "Spark Spread"

The day-to-day economics are governed by the "Spark Spread"—the difference in cost to deliver the same amount of useful heat with electricity versus a fired heater. This spread is highly volatile and regional, as seen in daily spot price charts for electricity grids (like ERCOT in Texas) and natural gas hubs.

Let's calculate the Spark Spread using the real-world spot prices for the "Southwest" region.

Figure 1: Natural Gas Prices

Figure 2: Electricity Prices

Example Calculation: Cost to Deliver 1 MMBtu of Useful Heat

Assumptions:

1. Electric Heater Efficiency: 98%

2. Fired Heater Thermal Efficiency: 85%

3. Electricity Price: $17.47 / MWh (or $0.0175 / kWh)

4. Natural Gas Price: $2.87 / MMBtu

1. Cost via Electric Heater (98% Efficiency):

To deliver 1 MMBtu of heat, we need 293 kWh of electricity.

Cost Electric =293kWh×$0.0175/kWh=$5.13

2. Cost via Fired Heater (85% Efficiency):

To deliver 1 MMBtu of heat, we must burn 1.18 MMBtu of fuel.

Cost Fired =1.18MMBtu×$2.87/MMBtu=$3.37

3. Resulting Spark Spread: $5.13−$3.37 = $1.76 per MMBtu of useful heat

The Strategic Variable: The Breakeven Carbon Price

This Spark Spread of $1.76 is the premium for operating on electricity. The strategic question is: at what carbon price does this premium disappear?

This is the Breakeven Carbon Price.

(see the calculation on the right)

This final number is a powerful tool. It tells a project manager that if they anticipate an actual or effective carbon price exceeding $28 per ton, the electric heater becomes the more economical option on an operating basis, justifying the initial investment.

Example Calculation: Breakeven Carbon Price

1. CO₂ Emitted per Unit of Useful Heat

Using a standard EPA emissions factor and our 85% heater efficiency, the fired heater emits 0.063 tons of CO₂ for every 1 MMBtu of useful heat it delivers.

2. Calculate the Breakeven Carbon Price

Divide the operational cost gap (or "Spark Spread") of $1.76/MMBtu by the emissions factor of 0.063 tons/MMBtu, we can determine the carbon tax required to reach parity.

This yields a breakeven price of: $27.93 per ton of CO₂.

As we've discussed, navigating the path to electrification is a significant engineering undertaking that goes far beyond selecting a piece of hardware. It requires a partner with a deep, integrated understanding of thermal design, process requirements, and the practical realities of refinery operations. With decades of specialized experience in fired thermal equipment, FIS is uniquely positioned to guide you through every stage of this process.

We help our clients by providing:

Technology Selection & Feasibility Studies

We work with your team to analyze your specific process needs, compare the capabilities and trade-offs of the different electric heater technologies, and develop the initial economic case, including preliminary CAPEX, OPEX, and carbon-breakeven calculations.

Detailed Heater Design & Engineering

Leveraging our core expertise in thermal and mechanical design, we can engineer the complete electric heater system. Whether the optimal solution is a high-temperature radiant box, a high-efficiency circulation heater, or a specialized indirect system, our team ensures the design is safe, reliable, and tailored to your exact service requirements.

Full Project Support

Our involvement can scale to your needs, from initial front-end engineering studies to providing a complete, fabricated, and tested heater system ready for installation. We bridge the gap between process, mechanical, and electrical engineering to ensure a seamless project.

The energy transition presents both challenges and opportunities. If you are beginning to explore the feasibility of an electric heater project, we invite you to start the conversation with us. Let our expertise guide your next step.

For more information, please contact the author at sidharth[at]heatflux[dot]com or visit the FIS website at www{dot}heatflux{dot}com